rfid stickers for manufacturing We offer end-to-end RFID solutions – including pre-tested RFID labels and tags made with the right materials and adhesives, along with the highest-performing inlays and chips – . 2992Hg. [CONFIRMED] Chase Freedom Unlimited & Freedom Flex are no longer embossed. .

0 · where to buy rfid sticker

1 · rfid stickers free download

2 · rfid stickers for tracking

3 · rfid stickers for inventory

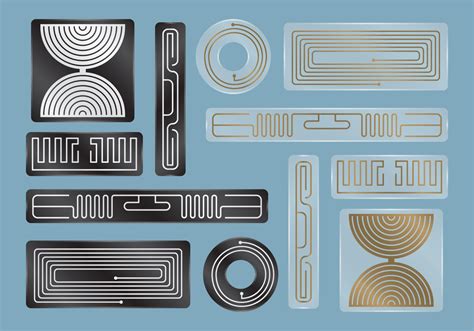

4 · rfid labels how they work

5 · rfid label examples

6 · printable rfid labels

7 · how to replace rfid sticker

NFC stands for Not Factory Cut. The cards are hand cut into the shape and size of a normal MTG card from an Uncut sheet of cards. Uncut sheets are given away as prizes for .

where to buy rfid sticker

We offer end-to-end RFID solutions – including pre-tested RFID labels and tags made with the right materials and adhesives, along with the highest-performing inlays and chips – . We’ve developed a detailed guide to break down the value of RFID tags in manufacturing. We’ll explain how RFID systems are used — and which benefits they provide .We offer end-to-end RFID solutions – including pre-tested RFID labels and tags made with the right materials and adhesives, along with the highest-performing inlays and chips – . We’ve developed a detailed guide to break down the value of RFID tags in manufacturing. We’ll explain how RFID systems are used — and which benefits they provide when implemented correctly.

RFID Tags allow you to determine, manage, and modify production steps to each unique project. If you are a company that undertakes a lot of custom jobs this can give your machinery or workers the information efficiently.RFID tags for manufacturing are designed for tracking throughout the Paint Shop, from pre-treatment, through cataphoresis, spray booth, to oven-drying and sandblasting cleaning.

opensc no smart card readers found

RFID labels are strong enough to withstand harsh conditions while transmitting information efficiently. Whether handling high temperatures in an intense manufacturing process or enduring icy cold outdoor environments, an RFID tag is more than capable.RFID tags enable automated management of raw materials, semi-finished products, and finished goods. When an item enters or exits a warehouse or moves to a production line, RFID readers can automatically record its movement, ensuring that inventory data is updated promptly. In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle. RFID tags in manufacturing have become an essential aspect of modern warehouse management, allowing companies to maintain accurate inventories, increase production efficiency, and reduce overall costs.

RFID Tags are applied to practically every product manufactured today, from apparel and furniture to medical goods, appliances and cars. RFID process control is an integral part of any automated manufacturing system for products on the factory floor. Radio-frequency identification (RFID) technology can optimize your supply chain by improving material flow and tracking damages. The more recent passive RFID tags serve as intelligent monitors that deliver accurate track and trace details throughout the supply chain.

We offer end-to-end RFID solutions – including pre-tested RFID labels and tags made with the right materials and adhesives, along with the highest-performing inlays and chips – . We’ve developed a detailed guide to break down the value of RFID tags in manufacturing. We’ll explain how RFID systems are used — and which benefits they provide when implemented correctly. RFID Tags allow you to determine, manage, and modify production steps to each unique project. If you are a company that undertakes a lot of custom jobs this can give your machinery or workers the information efficiently.RFID tags for manufacturing are designed for tracking throughout the Paint Shop, from pre-treatment, through cataphoresis, spray booth, to oven-drying and sandblasting cleaning.

RFID labels are strong enough to withstand harsh conditions while transmitting information efficiently. Whether handling high temperatures in an intense manufacturing process or enduring icy cold outdoor environments, an RFID tag is more than capable.

RFID tags enable automated management of raw materials, semi-finished products, and finished goods. When an item enters or exits a warehouse or moves to a production line, RFID readers can automatically record its movement, ensuring that inventory data is updated promptly.

In manufacturing, RFID systems employ radio waves to communicate between tags attached to physical objects and RFID readers. This seamless exchange of information enables real-time tracking, monitoring, and control of assets, components, and finished products throughout the production cycle. RFID tags in manufacturing have become an essential aspect of modern warehouse management, allowing companies to maintain accurate inventories, increase production efficiency, and reduce overall costs.RFID Tags are applied to practically every product manufactured today, from apparel and furniture to medical goods, appliances and cars. RFID process control is an integral part of any automated manufacturing system for products on the factory floor.

rfid stickers free download

rfid stickers for tracking

rfid stickers for inventory

$19.99

rfid stickers for manufacturing|rfid stickers free download