rfid inlay production machine Reel-to-reel converting equipment for dry and wet inlays and chip modules. Professional production of RFID labels, tags, tickets and contactless Smart Cards, NFC gaming cards. Converting speed range of up to 90,000 Smart Labels per . NFC business cards offer an innovative, digital way to share contact details. The NFC business card market is set to grow at a CAGR of 9.5% through 2031, indicating the fast adoption of NFC .

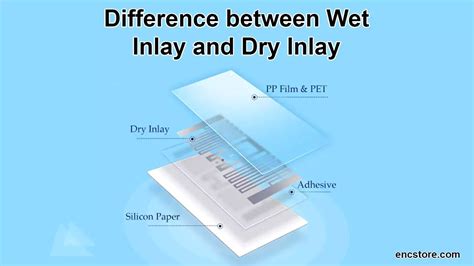

0 · wet rfid vs dry inlay

1 · rfid vs wet inlays

2 · rfid lost freight labels 4x6

3 · rfid labels for zebra printers

4 · rfid label manufacturers

5 · rfid inlays means

6 · rfid inlay manufacturers

7 · arizon rfid

$12.99

wet rfid vs dry inlay

The WCE2000 is our fastest and most productive high-volume system for wire embedding and RFID inlay production. You get unrivalled real-world throughput with up to 4,050 antennas per .The WCE150 is designed to produce RFID inlays for ID documents in the ID-1 and ID-3 form.

The WCE700 is a semi-automatic system designed to produce RFID inlays for ID document.

1993 nfc wild card game

Reel-to-reel converting equipment for dry and wet inlays and chip modules. Professional production of RFID labels, tags, tickets and contactless Smart Cards, NFC gaming cards. Converting speed range of up to 90,000 Smart Labels per .BW Bielomatik presents TagLiner – the highest capacity Inlay Die Bonding machine in the RFID industry. This RFID inlay manufacturing machine ensures extremely precise positioning, high bonding quality and usage of simpler and . TagLiner RFID Inlay Die Bonding Machine. The TagLiner is the highest capacity chip attach solution in the RFID industry. This RFID inlay manufacturing machine ensures extremely precise positioning, high bonding .Flexible platform for antenna embedding and RFID inlay production. The WCE2000 sets the standard for high-speed wire embedding and RFID inlay production: Superior quality, highest .

The WCE2000 is our fastest and most productive high-volume system for wire embedding and RFID inlay production. You get unrivalled real-world throughput with up to 4,050 antennas per hour as antenna embedding machine and up to 2,000 finished RFID inlays per hour as inlay manufacturing line.Reel-to-reel converting equipment for dry and wet inlays and chip modules. Professional production of RFID labels, tags, tickets and contactless Smart Cards, NFC gaming cards. Converting speed range of up to 90,000 Smart Labels per hour.

BW Bielomatik presents TagLiner – the highest capacity Inlay Die Bonding machine in the RFID industry. This RFID inlay manufacturing machine ensures extremely precise positioning, high bonding quality and usage of simpler and cheaper raw materials. TagLiner RFID Inlay Die Bonding Machine. The TagLiner is the highest capacity chip attach solution in the RFID industry. This RFID inlay manufacturing machine ensures extremely precise positioning, high bonding quality and usage of simpler and cheaper raw materials. View Details.

Flexible platform for antenna embedding and RFID inlay production. The WCE2000 sets the standard for high-speed wire embedding and RFID inlay production: Superior quality, highest accuracy and unmatched productivity at an unbeatable price-performance ratio.The WCE700 is a semi-automatic system designed to produce RFID inlays for ID documents (ID-1 and ID-3 format). Based on a 4-station roundtable concept with manual load and unload, this very economical solution can handle both small jobs and high-volume runs with ease.The MVW offline RFID inlay insertion equipment by Tamarack produces RFID labels, tickets, and tags on an offline platform. The label or ticket web(s) are brought the MVW where they are scanned to assure that the print registration matches the position of the inlay, once inserted.MB Palamax®, Mühlbauer’s Smart Factory solution, is devel-oped for card, tag or booklet productions, personalization fac-tories and semiconductor backend shop floors. Consisting of an NOSQL database, it is designed to set and collect process data to monitor and improve the efficiency of production and person-.

The MVW inline RFID inlay insertion equipment by Tamarack produces RFID labels, tickets, and tags in a single pass on your new or existing Flexo press. Tamarack Products is a leading manufacturer of RFID inlay insertion equipment that accommodate all inlay sizes.Inlay Production System - MTT. Produce your RFID inlays for any ePassport and Smart Card application: ID-1 and ID-3 format. Hybrid and Dual Interface Cards, contactless cards.

The WCE2000 is our fastest and most productive high-volume system for wire embedding and RFID inlay production. You get unrivalled real-world throughput with up to 4,050 antennas per hour as antenna embedding machine and up to 2,000 finished RFID inlays per hour as inlay manufacturing line.

Reel-to-reel converting equipment for dry and wet inlays and chip modules. Professional production of RFID labels, tags, tickets and contactless Smart Cards, NFC gaming cards. Converting speed range of up to 90,000 Smart Labels per hour.

BW Bielomatik presents TagLiner – the highest capacity Inlay Die Bonding machine in the RFID industry. This RFID inlay manufacturing machine ensures extremely precise positioning, high bonding quality and usage of simpler and cheaper raw materials. TagLiner RFID Inlay Die Bonding Machine. The TagLiner is the highest capacity chip attach solution in the RFID industry. This RFID inlay manufacturing machine ensures extremely precise positioning, high bonding quality and usage of simpler and cheaper raw materials. View Details.Flexible platform for antenna embedding and RFID inlay production. The WCE2000 sets the standard for high-speed wire embedding and RFID inlay production: Superior quality, highest accuracy and unmatched productivity at an unbeatable price-performance ratio.The WCE700 is a semi-automatic system designed to produce RFID inlays for ID documents (ID-1 and ID-3 format). Based on a 4-station roundtable concept with manual load and unload, this very economical solution can handle both small jobs and high-volume runs with ease.

The MVW offline RFID inlay insertion equipment by Tamarack produces RFID labels, tickets, and tags on an offline platform. The label or ticket web(s) are brought the MVW where they are scanned to assure that the print registration matches the position of the inlay, once inserted.MB Palamax®, Mühlbauer’s Smart Factory solution, is devel-oped for card, tag or booklet productions, personalization fac-tories and semiconductor backend shop floors. Consisting of an NOSQL database, it is designed to set and collect process data to monitor and improve the efficiency of production and person-.The MVW inline RFID inlay insertion equipment by Tamarack produces RFID labels, tickets, and tags in a single pass on your new or existing Flexo press. Tamarack Products is a leading manufacturer of RFID inlay insertion equipment that accommodate all inlay sizes.

2009 nfc wild card game

Contactless payments use short-range wireless technology to securely complete payments .

rfid inlay production machine|rfid vs wet inlays