rfid tracking shipment highway Efficiency is crucial to meet customer expectations and maintain a competitive edge in the ever . The Secure Element chip, an NFC chip that contains data such as the Secure Element .

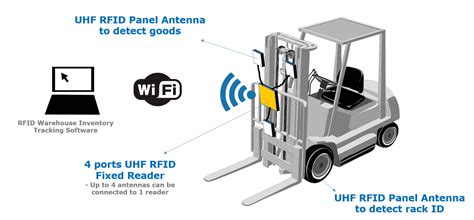

0 · rfid warehouse tracking system

1 · rfid tracking systems for inventory

2 · rfid tracking of inventory

3 · rfid labels for inventory tracking

4 · rfid inventory tracker

5 · rfid for warehouse inventory

6 · rfid asset tracking system

7 · active rfid tracking system

An NFC tag is a small integrated circuit consisting of a copper coil and some amount of storage. Data can be read or written to this tag only when another NFC device is brought near it because it .Share. certified_mother. • 2 yr. ago. Actually they are not safe. I repeat: they are NOT safe. These other posters do not have any idea what they are talking about. My daughter ordered some of these off E-Bay and used them on her Gameboy and it caused it to become completely unusable!

rfid warehouse tracking system

zelda botw amiibo nfc pvc tag cards switch

Efficiency is crucial to meet customer expectations and maintain a competitive edge in the ever .Enhanced Visibility: RFID tracking provides real-time visibility into the location and status of .Efficiency is crucial to meet customer expectations and maintain a competitive edge in the ever-evolving e-commerce market. In this article, we will explain how RFID can help maximize efficiency in shipment tracking, how it is a sustainable .Enhanced Visibility: RFID tracking provides real-time visibility into the location and status of shipping containers throughout the supply chain. Improved Efficiency: RFID technology streamlines container management by automating the tracking process, reducing manual errors, and optimizing operational efficiency.

RFID technology offers enhanced real-time tracking of goods in transit, allowing businesses to monitor shipments with pinpoint accuracy. By integrating RFID with GPS and IoT, enterprises can achieve comprehensive shipment visibility, ensuring .

RFID labeling enables automated tracking and monitoring of RTP movement, from point of origin to destination and back. This results in enhanced visibility, reduced loss, streamlined inventory management, and improved asset utilization. Logistics and supply chain management are increasingly turning to radio frequency identification (RFID) technology to provide real-time visibility into the locations and quantities of materials and items. The use of RFID tags can speed the inventory management process, reduce opportunities for human error and help reduce inventory shrinkage. When you use RFID tracking to monitor your shipments and check them in and out of inventory, you can isolate conditions that result in shipping damage or delays and mitigate them, as well as reducing your labor expenses and streamlining processes. RFID tracking is a game-changer for manufacturers, offering unparalleled visibility and control over assets and inventory. By understanding the mechanics of RFID tags, their applications, and the benefits they bring, you can leverage this technology to streamline operations and boost efficiency.

Switching over to RFID tracking could be the best thing your shipping company ever does. It’s so much easier to keep track of shipments and inventory when you can easily access accurate data about the state of the shipment in just a few seconds, and without even opening the box or container.

Implementing RAIN RFID tracking at the outbound dock door automates outbound shipment verification and eliminates the need for manual steps or line-of-sight access, so it’s faster, more efficient, and more accurate than manual options. How RAIN RFID Solutions Work at the Outbound Dock Door. Next Steps. What Is RFID Tracking? RFID tracking is a technology that uses radio waves to track and identify objects or people. It’s like a high-tech version of playing hide-and-seek — except instead of shouting “ready or not, here I come!” you’re using radio waves to .Efficiency is crucial to meet customer expectations and maintain a competitive edge in the ever-evolving e-commerce market. In this article, we will explain how RFID can help maximize efficiency in shipment tracking, how it is a sustainable .

rfid tracking systems for inventory

Enhanced Visibility: RFID tracking provides real-time visibility into the location and status of shipping containers throughout the supply chain. Improved Efficiency: RFID technology streamlines container management by automating the tracking process, reducing manual errors, and optimizing operational efficiency.RFID technology offers enhanced real-time tracking of goods in transit, allowing businesses to monitor shipments with pinpoint accuracy. By integrating RFID with GPS and IoT, enterprises can achieve comprehensive shipment visibility, ensuring .RFID labeling enables automated tracking and monitoring of RTP movement, from point of origin to destination and back. This results in enhanced visibility, reduced loss, streamlined inventory management, and improved asset utilization. Logistics and supply chain management are increasingly turning to radio frequency identification (RFID) technology to provide real-time visibility into the locations and quantities of materials and items. The use of RFID tags can speed the inventory management process, reduce opportunities for human error and help reduce inventory shrinkage.

When you use RFID tracking to monitor your shipments and check them in and out of inventory, you can isolate conditions that result in shipping damage or delays and mitigate them, as well as reducing your labor expenses and streamlining processes.

RFID tracking is a game-changer for manufacturers, offering unparalleled visibility and control over assets and inventory. By understanding the mechanics of RFID tags, their applications, and the benefits they bring, you can leverage this technology to streamline operations and boost efficiency. Switching over to RFID tracking could be the best thing your shipping company ever does. It’s so much easier to keep track of shipments and inventory when you can easily access accurate data about the state of the shipment in just a few seconds, and without even opening the box or container.

Implementing RAIN RFID tracking at the outbound dock door automates outbound shipment verification and eliminates the need for manual steps or line-of-sight access, so it’s faster, more efficient, and more accurate than manual options. How RAIN RFID Solutions Work at the Outbound Dock Door.

The NXP sensing portfolio combines sensing with NFC connectivity to create .

rfid tracking shipment highway|rfid for warehouse inventory