rfid tags are they traceable As a sort of first passive RFID system, Royal Air Force (RAF) members noticed . Fully NFC capable phones support 3 modes of operation: Reader / Writer: the phone reads data from an NFC tag or writes data back to it. The Core NFC API of Apple only .In this tutorial, we’ll walk through the steps of how to scan NFC tags in an Android mobile app using Kotlin. Photo by 12photostory on Unsplash Step-1 : Add NFC Permission to AndroidManifest.xml

0 · types of rfid tracking

1 · rfid tracking tags cost

2 · rfid tracking tags

3 · rfid tracking software

4 · rfid tracking

5 · rfid tags vs barcodes

6 · rfid tags cost

7 · rfid tags

In this guide you’ll learn how to configure Smart Card authentication using SSSD as authentication daemon in a way that can be used both for user interface access via GDM .The ACR122U NFC Reader is a PC-linked contactless smart card reader/writer developed based on 13.56 MHz Contactless (RFID) Technology. Compliant with the ISO/IEC18092 standard for Near Field Communication (NFC), it supports not only MIFARE® and ISO 14443 A and B .

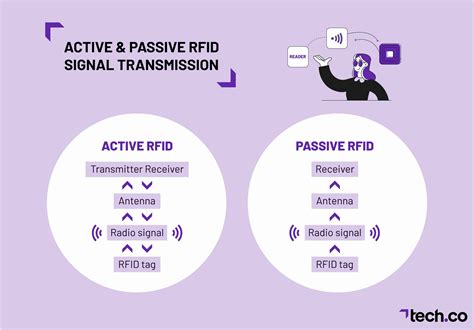

The basic purpose of an RFID system is the distinctive traceability of objects, animals and humans, providing them with an individual number within the RFID tag they are attached with.As a sort of first passive RFID system, Royal Air Force (RAF) members noticed .Part II: The RFID tags applications. In the previous article, the first part of this .To sum, there are three types of RFID tags: active, passive and semi-active. The .

In short, RFID solutions are products for specific RFID systems. As an example, .The basic purpose of an RFID system is the distinctive traceability of objects, animals and humans, providing them with an individual number within the RFID tag they are attached with. Essentially, RFID uses radio frequency waves to transfer data wirelessly between a scanner and a tag. In contrast to barcode technology, which requires a stationary scanner, RFID tags can be pinged from anywhere in the world, allowing companies to track real-time movement through the supply chain. RFID tags are small, passive devices that are attached to the assets that need to be track and trace. These tags contain a microchip and an antenna. The microchip stores the unique identification code for the assets, which is transmitted back to the RFID reader by the antenna.

RFID tags can be read by scanners at fixed points and can automatically track items from one point to another within a defined geographic space, for example components moving through a factory or or goods in a warehouse. RFID tracking involves attaching an RFID tag loaded with data, including name, condition, amount, and location, to relevant assets. The RFID reader captures the stored data through pulsating. To break it down, RFID asset tracking uses RFID tags and readers to track assets. It makes tracking faster as it doesn’t need line of sight and multiple assets can be tracked at the same time from a distance. It enables automatically updating the availability and location of the asset in your asset register without human intervention. In this article, we will delve into the fundamentals of RFID tag tracking, explore different types of tracking systems, discuss the challenges associated with RFID tag tracking, and provide best practices to ensure optimal performance.

types of rfid tracking

RFID enabled supply chain traceability isn’t just a theoretical conception; it’s revolutionizing different industries. Pharmaceutical companies are using RFID to track individual medicine packages, assuring product authenticity, precluding counterfeiting, and .

An RFID tag can track raw materials and parts within a facility, limiting the need for reordering lost parts. Additionally, companies can track assets (such as vehicles, containers, or equipment) in real-time, which improves supply chain visibility and reduces the risk of loss or theft. Active RFID tags are “always on” and actively transmit signals to RFID readers, enabling longer read ranges and real-time tracking capabilities.

The basic purpose of an RFID system is the distinctive traceability of objects, animals and humans, providing them with an individual number within the RFID tag they are attached with. Essentially, RFID uses radio frequency waves to transfer data wirelessly between a scanner and a tag. In contrast to barcode technology, which requires a stationary scanner, RFID tags can be pinged from anywhere in the world, allowing companies to track real-time movement through the supply chain. RFID tags are small, passive devices that are attached to the assets that need to be track and trace. These tags contain a microchip and an antenna. The microchip stores the unique identification code for the assets, which is transmitted back to the RFID reader by the antenna.RFID tags can be read by scanners at fixed points and can automatically track items from one point to another within a defined geographic space, for example components moving through a factory or or goods in a warehouse.

rfid tracking tags cost

RFID tracking involves attaching an RFID tag loaded with data, including name, condition, amount, and location, to relevant assets. The RFID reader captures the stored data through pulsating.

To break it down, RFID asset tracking uses RFID tags and readers to track assets. It makes tracking faster as it doesn’t need line of sight and multiple assets can be tracked at the same time from a distance. It enables automatically updating the availability and location of the asset in your asset register without human intervention. In this article, we will delve into the fundamentals of RFID tag tracking, explore different types of tracking systems, discuss the challenges associated with RFID tag tracking, and provide best practices to ensure optimal performance.

exxon smart card +

RFID enabled supply chain traceability isn’t just a theoretical conception; it’s revolutionizing different industries. Pharmaceutical companies are using RFID to track individual medicine packages, assuring product authenticity, precluding counterfeiting, and . An RFID tag can track raw materials and parts within a facility, limiting the need for reordering lost parts. Additionally, companies can track assets (such as vehicles, containers, or equipment) in real-time, which improves supply chain visibility and reduces the risk of loss or theft.

rfid tracking tags

rfid tracking software

rfid tracking

rfid tags vs barcodes

There are lots of ways to use the iphone to scan 125kHz tags. ***edit***. Yep, I was wrong. iphone can read nfc data but not 125kHz RFID tags. nfc and RFID are confusing. Sorry for the mislead. I will say that when I googled "how to read .

rfid tags are they traceable|rfid tracking