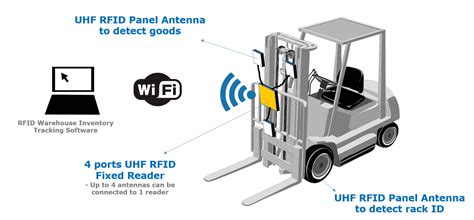

rfid tags warehouse management With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously. 15 votes, 12 comments. 7.2K subscribers in the LGG3 community. Discussion of LG's 2014 flagship smartphone, the LG G3

0 · rfid warehouse tracking system

1 · rfid warehouse management system requirements

2 · rfid warehouse management system benefits

3 · rfid warehouse inventory system

4 · rfid warehouse inventory management

5 · rfid system for warehouse management

6 · rfid for warehouse inventory

7 · rfid based warehouse management system

iOS 15.4.1 background reading. So this seems to be a commonly complained about issue, but I can read NFC tags fine through app, but background NFC reading seems to work maybe 1 in .

With an RFID warehouse management tracking system, items can be scanned and catalogued . What is the use of RFID in warehouse management? In warehouse .Incorporating RFID into warehouse management significantly improves efficiency by .With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

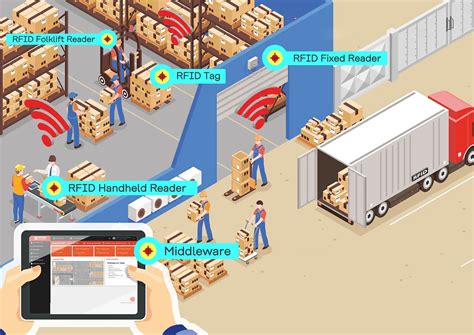

What is the use of RFID in warehouse management? In warehouse management, RFID strengthens and streamlines myriad activities – from order dispatch, and stock location, to cycle counting. It also trims down human errors, giving a thrust to overall efficiency.There are some good reasons to consider using RFID tags for warehouse inventory management. RFID tags don’t need line of sight: It’s possible to read the data from an RFID tag from a distance. This means inventory can be taken without a worker scanning each item.

Incorporating RFID into warehouse management significantly improves efficiency by automating tasks such as tracking goods, monitoring stock levels, and minimizing human error. This technology enables warehouse managers to quickly locate and identify items, accelerating the supply chain process. RFID Warehouse Management is a great way to improve overall efficiency. To learn about the pros & cons - Click Here! If you’ve wondered whether or not RFID tagging is right for asset management in your warehouse, we’ve got answers for you.RFID helps streamline warehouse operations by reducing the time needed for stocktaking, locating items, and processing shipments. Warehouse staff no longer need to manually scan or search for products, freeing them to focus on value-added tasks such as quality checks or customer service. RFID tags used in a warehouse produce several key advantages. For starters, RFID is more precise, reducing the risk of human error. It maintains time with automatic processes that communicate with warehouse software.

The implementation of RFID technology revolutionizes the real-time tracking and visibility of inventory within a warehouse. With RFID, tagged items can be monitored constantly, providing up-to-the-minute location data, which in turn significantly reduces the likelihood of lost or misplaced goods. RFID technology undeniably transforms warehouse management, significantly improving inventory accuracy, operational speed, and profitability. Its impact is far-reaching, from streamlining day-to-day operations to enabling strategic decision-making based on real-time data. RFID tags and label products are becoming increasingly popular for warehouse management as a way to maintain control of your inventory. What is RFID? Radio-frequency identification (RFID) uses electromagnetic fields to automatically identify and track tags and labels attached to objects.With an RFID warehouse management tracking system, items can be scanned and catalogued from anywhere, even when they’re hidden behind boxes or pallets. RFID tags can also be detected and read remotely and simultaneously.

What is the use of RFID in warehouse management? In warehouse management, RFID strengthens and streamlines myriad activities – from order dispatch, and stock location, to cycle counting. It also trims down human errors, giving a thrust to overall efficiency.

rfid warehouse tracking system

rfid warehouse management system requirements

There are some good reasons to consider using RFID tags for warehouse inventory management. RFID tags don’t need line of sight: It’s possible to read the data from an RFID tag from a distance. This means inventory can be taken without a worker scanning each item.Incorporating RFID into warehouse management significantly improves efficiency by automating tasks such as tracking goods, monitoring stock levels, and minimizing human error. This technology enables warehouse managers to quickly locate and identify items, accelerating the supply chain process.

RFID Warehouse Management is a great way to improve overall efficiency. To learn about the pros & cons - Click Here! If you’ve wondered whether or not RFID tagging is right for asset management in your warehouse, we’ve got answers for you.

RFID helps streamline warehouse operations by reducing the time needed for stocktaking, locating items, and processing shipments. Warehouse staff no longer need to manually scan or search for products, freeing them to focus on value-added tasks such as quality checks or customer service. RFID tags used in a warehouse produce several key advantages. For starters, RFID is more precise, reducing the risk of human error. It maintains time with automatic processes that communicate with warehouse software. The implementation of RFID technology revolutionizes the real-time tracking and visibility of inventory within a warehouse. With RFID, tagged items can be monitored constantly, providing up-to-the-minute location data, which in turn significantly reduces the likelihood of lost or misplaced goods.

RFID technology undeniably transforms warehouse management, significantly improving inventory accuracy, operational speed, and profitability. Its impact is far-reaching, from streamlining day-to-day operations to enabling strategic decision-making based on real-time data.

rfid warehouse management system benefits

hp keyboard smart card reader driver windows 7

Posted on Nov 1, 2021 12:10 PM. On your iPhone, open the Shortcuts app. Tap on the Automation tab at the bottom of your screen. Tap on Create Personal Automation. Scroll down and select NFC. Tap on Scan. Put .

rfid tags warehouse management|rfid warehouse tracking system