smart card module tape Contact C6 & C8, Contactless, Dual Interface, and RFID Tag Modules. Globtop and Dam & Fill machines with in-line 100% thickness inspection. Proven bill of materials that Pass CQM & ISO Reliability standards for both module and card level. On this video you can know How to Turn on or Turn Off NFC on Samsung Gear .

0 · Tape for specialty smart card and DI card applications

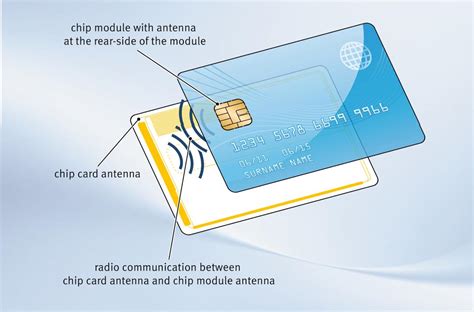

1 · Smart Cards

2 · SMART CARD PRODUCTION TECHNOLOGY

I just bought some NFC tags and my new iphone 12 pro reads them through .

Streamline your process for assembling dual interface smart cards with our specially developed .Contact C6 & C8, Contactless, Dual Interface, and RFID Tag Modules. Globtop and Dam & Fill machines with in-line 100% thickness inspection. Proven bill of materials that Pass CQM & ISO Reliability standards for both module and card .

Streamline your process for assembling dual interface smart cards with our specially developed adhesive tapes that combine chip module embedding and antenna connection in a single step. We even offer an anisotropic conductive hotmelt film which is easily integrated into most assembly lines with no investment cost.Contact C6 & C8, Contactless, Dual Interface, and RFID Tag Modules. Globtop and Dam & Fill machines with in-line 100% thickness inspection. Proven bill of materials that Pass CQM & ISO Reliability standards for both module and card level.¤ Integrated spooling systems for module tape & spacer tape ¤ Highly flexible testing solution for various IC Module applications ¤ 4-fold test heads for 9.5 & 14.25 mm pitch contact IC ModulesDELO®’s smart card products have been tested and proven reliable. Our customers have tested and passed the most diffi cult tests in the industry: TMCL temperature cycling. Thermal storage. THB temperature and humidity storage. Pressure cooker.

Our adhesive tape technology is the most flexible, clean and easy solution for manufacturing processes. For module embedding, it also guarantees card quality and long term resistance, thereby reinforcing smart card security.Henkel’s new smart card die attach formulation is designed for exceptionally fast processing and compatibility with the most widely used encapsulants in the market, including Henkel encapsulants, and ensures low contact angles for complete wetting and robust protection.Smart card contact-based controller modules. P-M4.8. P-M4.8. Overview. Contact-based module 8 contacts Epoxy Tape Wire Bond Mold. Summary of Features. 14.25mm. 13 x 11.8mm. max. 600?m.

the smart card milling system sCm 5001 is used for automatic milling of cavities for iC modules in plastic cards. the system is perfectly suitable for all contact cards, dual interface cards and multi-sim cards. this system features a highly economical card milling process for medium to large sized production tasks.PPI Adhesive Products have developed a range of non-conductive heat-activated tapes for ID Cards, Sim Cards, and Transport Cards. Our Heat-sealing film is suitable for the chip module embedding process for plastic contact cards commonly made from PVC, ABS & PC materials.Permanent bonding of a chip module into the cavity of substrates is crucial for all smart-card manufacturers to ensure that the cards function properly in daily applications. For contact card assembly processes, we offer tesa HAF®, a complete range of Heat-Activated Films with a high level of bonding strength to a variety of card substrates.

Tape for specialty smart card and DI card applications

Streamline your process for assembling dual interface smart cards with our specially developed adhesive tapes that combine chip module embedding and antenna connection in a single step. We even offer an anisotropic conductive hotmelt film which is easily integrated into most assembly lines with no investment cost.Contact C6 & C8, Contactless, Dual Interface, and RFID Tag Modules. Globtop and Dam & Fill machines with in-line 100% thickness inspection. Proven bill of materials that Pass CQM & ISO Reliability standards for both module and card level.

¤ Integrated spooling systems for module tape & spacer tape ¤ Highly flexible testing solution for various IC Module applications ¤ 4-fold test heads for 9.5 & 14.25 mm pitch contact IC Modules

DELO®’s smart card products have been tested and proven reliable. Our customers have tested and passed the most diffi cult tests in the industry: TMCL temperature cycling. Thermal storage. THB temperature and humidity storage. Pressure cooker.

Our adhesive tape technology is the most flexible, clean and easy solution for manufacturing processes. For module embedding, it also guarantees card quality and long term resistance, thereby reinforcing smart card security.

Henkel’s new smart card die attach formulation is designed for exceptionally fast processing and compatibility with the most widely used encapsulants in the market, including Henkel encapsulants, and ensures low contact angles for complete wetting and robust protection.Smart card contact-based controller modules. P-M4.8. P-M4.8. Overview. Contact-based module 8 contacts Epoxy Tape Wire Bond Mold. Summary of Features. 14.25mm. 13 x 11.8mm. max. 600?m.the smart card milling system sCm 5001 is used for automatic milling of cavities for iC modules in plastic cards. the system is perfectly suitable for all contact cards, dual interface cards and multi-sim cards. this system features a highly economical card milling process for medium to large sized production tasks.

PPI Adhesive Products have developed a range of non-conductive heat-activated tapes for ID Cards, Sim Cards, and Transport Cards. Our Heat-sealing film is suitable for the chip module embedding process for plastic contact cards commonly made from PVC, ABS & PC materials.

Smart Cards

brta smart card check sms

c# read smart card certificate

csd canteen smart card tracking

SMART CARD PRODUCTION TECHNOLOGY

It's to the right of the cameras and as long as I hold the upper third of my phone against the .

smart card module tape|SMART CARD PRODUCTION TECHNOLOGY