wet inlay rfid tags Most Metalcraft RFID tags can be made using either a wet RFID inlay or a dry RFID inlay. There are several factors to look at when deciding which type of inlay to use. For example, the RFID tag manufacturing process may require one type of inlay versus another. The position of the sensor differs from model to model. For some models, the exact position is difficult to determine. Let us explain. For the recently released iPhones, you need to tilt your device towards the reader such that the top part of your iPhone faces . See more

0 · wet vs rfid inlays

1 · wet vs dry rfid adhesive

2 · rfid tags

3 · rfid labels

4 · avery dennison rfid inlay

5 · avery dennison rfid

$6.40

RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any RFID Wet Inlay can also be converted into a paper or synthetic face label. Atlas offers almost .The Vulcan RFID Flame UHF RFID White Wet Inlay is equipped with the optimal, .

Most Metalcraft RFID tags can be made using either a wet RFID inlay or a dry RFID inlay. There are several factors to look at when deciding which type of inlay to use. For example, the RFID tag manufacturing process may .RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any RFID Wet Inlay can also be converted into a paper or synthetic face label. Atlas offers almost every RFID Wet Inlay on the market, including the Smartrac Dogbone and Alien Squiggle. Most Metalcraft RFID tags can be made using either a wet RFID inlay or a dry RFID inlay. There are several factors to look at when deciding which type of inlay to use. For example, the RFID tag manufacturing process may require one type of inlay versus another.

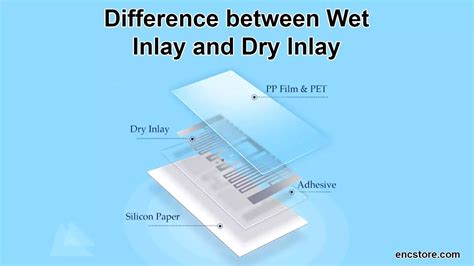

In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing materials, durability, cost, and applicable environment.RFID inlays and tags for all frequencies, applications, and preferences. Our extensive RFID technology portfolio covers a wide range of inlay designs for operation in the UHF, HF and NFC frequency bands, and are commonly found in a wide range of industries - including apparel, beauty and personal care, food, automotive, aviation .

Wet inlay RFID tags are a type of RFID (Radio Frequency Identification) tag consisting of an integrated circuit (IC) chip attached to an antenna, which is then sandwiched between two layers of material, usually paper or plastic.

An RFID dry inlay is essentially an RFID chip and antenna laminated onto a substrate. Unlike wet inlays, dry inlays do not have an adhesive layer. This makes them highly versatile and customizable, suitable for integration into various end products.` Wet versus dry — Adhesive-backed inlays are most common and can be used when no ancillary operations are required. These “wet” inlays typically come in rolls and can be quickly peeled off and adhered to the product. A wet inlay is delivered to the converter attached to a .

wet vs rfid inlays

build an rfid system

Wet inlay, due to its convenient usage and excellent performance, has become a preferred RFID solution for many enterprises. This article uses the Alien Higgs®EC UHF RFID Wet Inlay as an example to help users better understand how to use RFID wet inlay and some key considerations.The Avery Dennison Smartrac DogBone RFID Wet Inlays excel with superior performance inside of demanding environments and on tough-to-tag materials, due to the inlay's exceptional tolerance against the detuning effect of high dielectric materials.

Wet Inlays – a Pressure Sensitive Inlays – same as Dry Inlay above, with the addition of a “wet” adhesive backing and liner. Encapsulated or Durable Finished Transponders – an inlay with the addition of a durable encapsulate for longer tag life.RFID Wet Inlays are best for applications where a low-cost “peel-and-stick” tag is needed. Any RFID Wet Inlay can also be converted into a paper or synthetic face label. Atlas offers almost every RFID Wet Inlay on the market, including the Smartrac Dogbone and Alien Squiggle. Most Metalcraft RFID tags can be made using either a wet RFID inlay or a dry RFID inlay. There are several factors to look at when deciding which type of inlay to use. For example, the RFID tag manufacturing process may require one type of inlay versus another.

In the wide application of RFID technology, wet inlay and dry inlay are two common forms of tags, each with its advantages. This article will comprehensively compare the two inlays and explore the differences in their manufacturing materials, durability, cost, and applicable environment.RFID inlays and tags for all frequencies, applications, and preferences. Our extensive RFID technology portfolio covers a wide range of inlay designs for operation in the UHF, HF and NFC frequency bands, and are commonly found in a wide range of industries - including apparel, beauty and personal care, food, automotive, aviation .

ford rfid system

Wet inlay RFID tags are a type of RFID (Radio Frequency Identification) tag consisting of an integrated circuit (IC) chip attached to an antenna, which is then sandwiched between two layers of material, usually paper or plastic.An RFID dry inlay is essentially an RFID chip and antenna laminated onto a substrate. Unlike wet inlays, dry inlays do not have an adhesive layer. This makes them highly versatile and customizable, suitable for integration into various end products.` Wet versus dry — Adhesive-backed inlays are most common and can be used when no ancillary operations are required. These “wet” inlays typically come in rolls and can be quickly peeled off and adhered to the product. A wet inlay is delivered to the converter attached to a .Wet inlay, due to its convenient usage and excellent performance, has become a preferred RFID solution for many enterprises. This article uses the Alien Higgs®EC UHF RFID Wet Inlay as an example to help users better understand how to use RFID wet inlay and some key considerations.

The Avery Dennison Smartrac DogBone RFID Wet Inlays excel with superior performance inside of demanding environments and on tough-to-tag materials, due to the inlay's exceptional tolerance against the detuning effect of high dielectric materials.

wet vs dry rfid adhesive

bolt rfid timing system

The ACR1255U-J1 ACS Secure Bluetooth® NFC Reader supports ISO 14443 Type A and B smart cards, MIFARE®, FeliCa, and most NFC tags and devices compliant with ISO 18092 standard. The ACR1255U-J1 has both .SDK. The ACR1252U USB NFC Reader III is an NFC Forum-certified PC-linked .

wet inlay rfid tags|wet vs dry rfid adhesive